Casting Type Resins

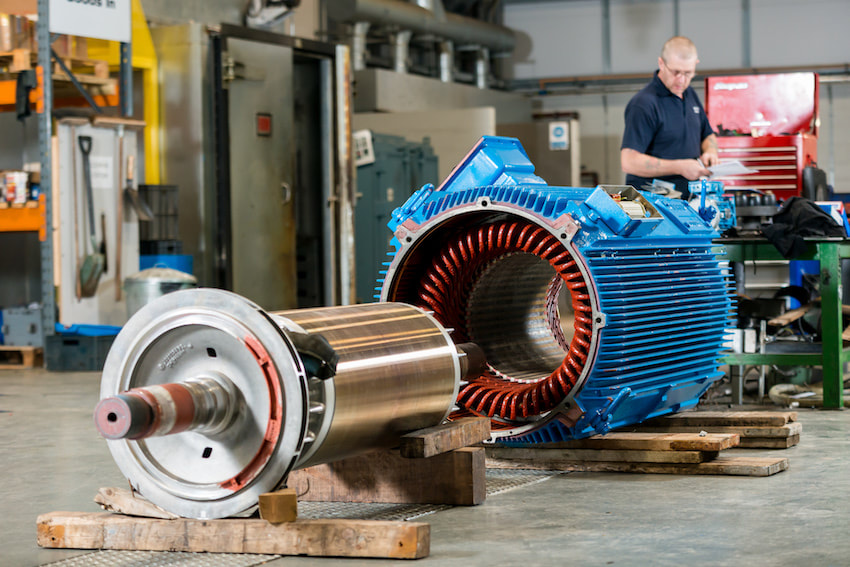

Cast type resin is among the epoxy resins used for electric motor insulation. With the formulation and application of a suitable casting type epoxy resin, it is possible to guarantee the thermal distribution of the engine and a greater resistance to shocks, vibrations, chemicals, water, dust and other external influences.

Properties of Cast Epoxy Resins

Provides Electrical Insulation

The first advantage of cast type resins used in electric motor insulation is that they provide excellent electrical insulation. Air or voids can create partial losses between ground and primary insulation, compromising performance and engine life. Thanks to the casting type resin, the resin will spread to all internal cavities of the engine (especially the undercuts and windings). In this way, an excellent electrical insulation is provided.

Provides Thermal Dissipation

Cast-type epoxy resin is a great thermal conductive material. This means that the motors run at lower temperature and therefore have higher endurance.

Protects Engine and Extends Its Life

Your electric motor will have a very long life! Cast type epoxy resin protects electric motors from chemicals, moisture, dust and impacts. In addition, the cast-type epoxy resin greatly reduces vibrations and noise produced by the engine and provides greater mechanical stability, providing significant structural reinforcement.

Provides High Security

With some cast epoxy resins it is possible to have flame retardant properties, which is an added benefit for established applications such as electric vehicles and shipping.